I’m currently going through the dreaded emotional rollercoaster

and the physical endurance test of clearing out mom’s house.

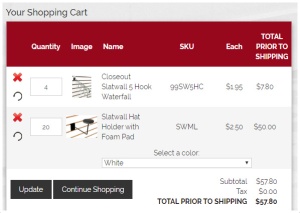

It’s a double-edged sword.

I get to at long-last bring my own belongings out of storage to make it feel like home for me, but it also means parting with most of mom’s belongings.

Which often feels like I’m erasing her.

Tears are frequent.

I feel like I should share the path of change, so,

first- mom’s room before & after.

I sold her [inherited] bedroom furniture. . . . . to a nurse.

And that’s probably the only part that she would have liked.

The next morning I had a meltdown~ “WHAT– did I do?“

These were early pictures of setting it up and styling it for her~

no idea what happened to the pretty finished shots–?

The furniture passed to her from our beloved great auntie who bought it brand new to go in the house she was building in 1910.

Below is the way the room has been REdone.

With MY things, but, in her honor.

The foundation of the room got a fresh painted job because of all the holes that needed patching. This time the white has a warmer tone. The drapes were already changed to the soft, sheer white with lace, the hand-hooked wool garden rug remained.

The dresser, nightstand, and antique French bergère were pieces already dedicated to “her room” in my former house.

The bed was a long-ago project I posted on. It was an aMAZing mirror that had been broken- I bought the frame to make into a bed!

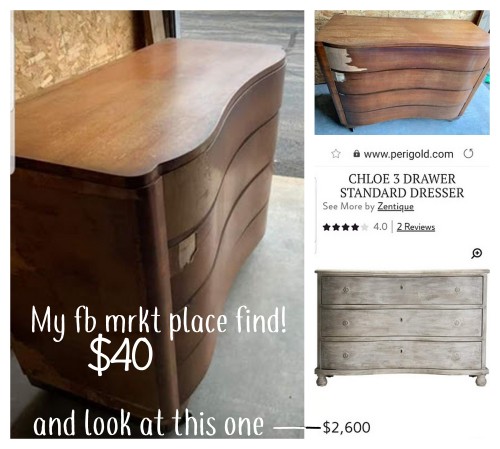

The looong cabinet was a $13, 5-yrs-ago Craigslist find that finally came out of my stashes, got a good cleaning, some repairs, and fresh paint job!

Many meaningful things have found their place in here–I just couldn’t let all her belongings go. I find myself sitting quietly in her room with regularity, and take comfort in being around her—stuff.

I struggled with letting a LOT of her things go and find I’m letting more of my own things go to strike a balance.

Missing you so much mom—

wish Heaven had visiting hours.

I love this last pre-cancer picture.

Want to see the “new” Living room?

That’s a big change, come on back—

Catherine